기업의 더 효율적인 소프트웨어

선택을 위한 17년 지원 경험

PerformOEE Smart Factory Software

PerformOEE Smart Factory Software은(는) 무엇인가요?

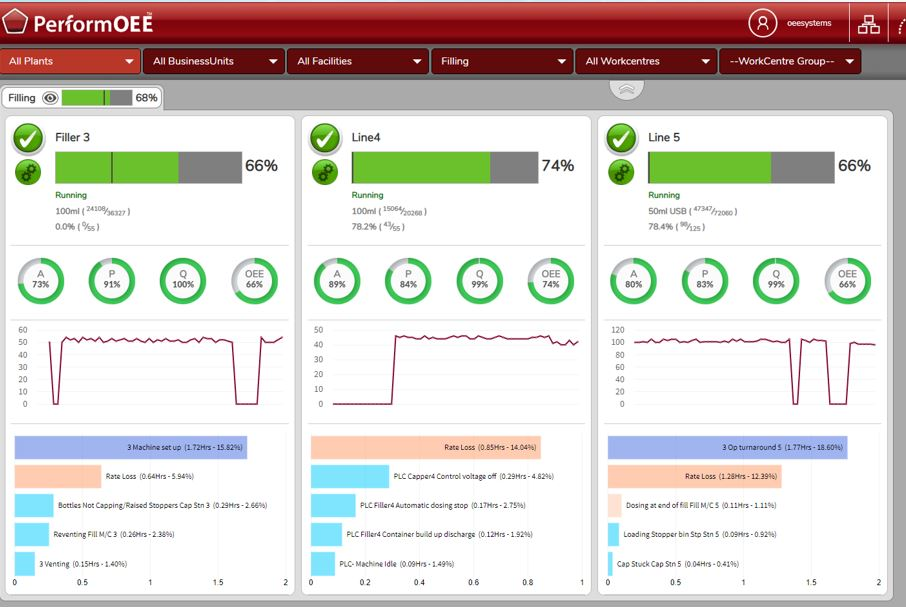

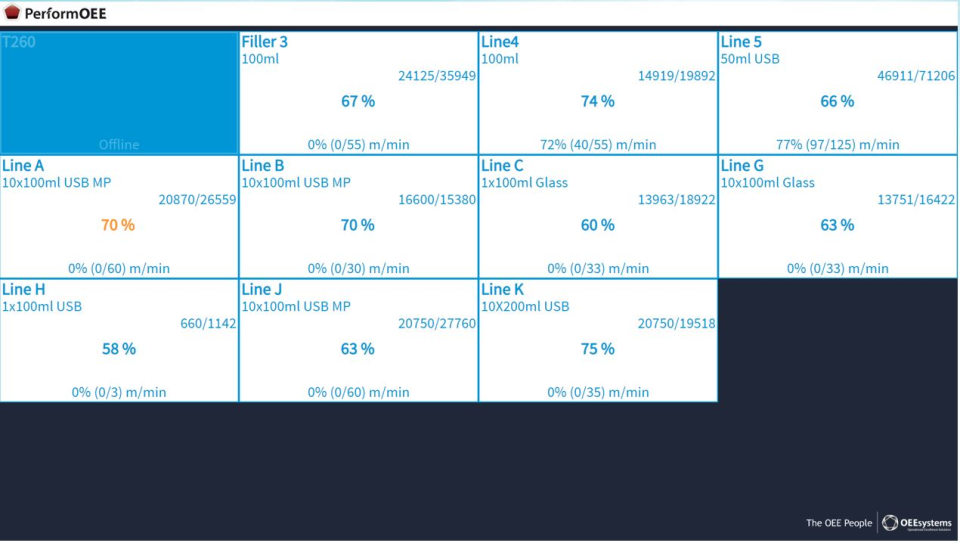

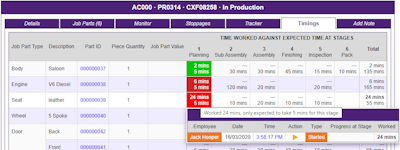

PerformOEE는 실시간 성능 문제를 강조하여 제어가 가능하도록 합니다. 당사의 원팀 접근법은 올바른 대응 방식에 대한 해법을 제공합니다. 능동적으로 대응하면 문제를 보다 효과적으로 관리할 수 있습니다.

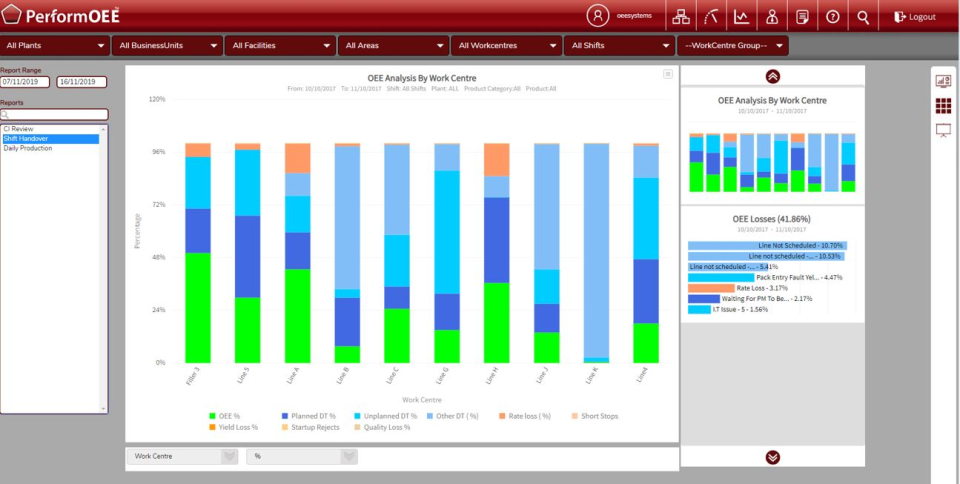

PerformOEE는 '생각하는 대로 클릭' 빅 데이터 드릴다운 기능으로 지속적인 개선을 지원합니다. 당사의 '데이터에 따르는' 접근 방식은 개선 기회를 식별합니다.

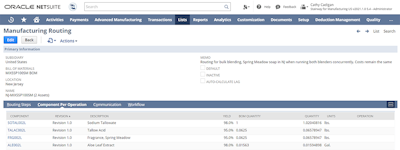

PerformOEE는 예측 유지보수, 상태 기반 모니터링, AI 및 SPC를 결합하여 CPC를 통한 변화를 제공합니다.

PerformOEE Smart Factory Software은(는) 누가 사용하나요?

역량 증가, 비용 절감, 품질 개선 및 지속적인 개선을 추구하는 진취적인 제조업체를 대상으로 합니다. 일반적으로 대량 생산 고객 또는 주기 시간 기반 고객입니다.

PerformOEE Smart Factory Software에 대해 확실하지 않으세요?

인기 있는 대안 제품과 비교

PerformOEE Smart Factory Software

PerformOEE Smart Factory Software 리뷰

평균 점수

회사 규모(직원 수)별 리뷰

- <50

- 51-200

- 201-1,000

- >1,001

점수별 리뷰 찾기

Stamping Press & Rolling Mill Use of OEEsystems

주석: Customer service was excellent. We had biweekly calls long after implementation with OEEsystems. They were able to customize the service as we changed our needs.

장점:

The up to the minute reporting of information on the machinery helps track what's going on in the factory. I could have the dashboard up on a monitor at my desk and know what's going on at each machine in real time. The reporting would also help for month end reporting, but also what problems to tackle to see an uptick in OEE.

단점:

OEE systems was a perfect fit for our stamping presses. It was easy to implement and even easier to use. As for the rolling mills, it was a much more manual implementation and is not as intuitive in the collection of data. However, the support team at OEE was there to help with whatever we need.

Excellent for Order & Equipment Tracking as well as Quality Analytics

주석: OEE improvement was a critical reason we looked at PerformOEE because of the need to meet high demand seasons orders (on time delivery). The improvements were primarily made around operations organisation, addressing equipment reliability and driving significant quality improvements. The system is embedded in the culture of the company across all manufacturing and support departments.

장점:

For us it is critical when it comes to OEE measurement of our production floor that we also require a reliable system that gives 100% accuracy on Order Tracking, automated data collection of Counts, Alarms and Quality. Quality is a key element of our process and PerformOEE gives us strong insights as well as early warnings when these types of issues arise. The team in OEEsystems take a lot of time to understanding our process and particular challenges we had in relation to data collection. They worked with us to develop and configured the software to meet these challenges as and when they arose. We use the software at the centre of all Shift Handover, Daily Production and Improvement team meetings for monitoring production and deciding on which projects to invest.

단점:

I did not really come across any significant shortcomings in the software that I would classify as like least.

Highly Recommend for driving Continous Improvement culture

주석:

I’ve seen many applications that fall well short in terms of meeting the requirements of Production Floor operatives to the Senior Management Teams.

PerformOEE delivers with a big help from OEEsystems and their implementation methodology which focuses on Operations and Business Priorities.

Finally the analytics engine provided make it easy for users to identify opportunities for improvement and this gives great buy-in from all the users.

장점:

As a consultant I have clients internationally whom use this software for their Continuous Improvement initiatives and in my role working for these clients I use the software both to directly drive improvements as well as instil a Continuous Improvement methodology in the business. The Online module is strong for real time performance improvement as users are notified of loss or potential issues and they can take corrective action quickly. The Dashbaord module can be tailored for business meeting using the Report Pack facility. I encourage use of the tool at Shift Handover meeting, Daily Production meeting, Weekly Reviews and Quarterly Continuous Improvement Reviews. The whole Operations team trust the data and this greatly assists progress of initiatives. I have recommended and introduced the software to a number of clients also based on my experience of which many trialled and procured the product.

단점:

When deploying the software there are many features of which many are not immediately applicable so it is important to develop a roadmap of which features to enable and which one’s to delay based on your priorities. OEEsystems project manage this aspect of the implementations particularly well.

Know where your Manufacturing Losses are and how to improve

주석:

This software is now so embedded in out Production teams it provides The Tool for production meetings, maintenance guidance and Continuous Improvement activities.

Implementation from the earliest stages of installing and turning on the Production equipment has proven to increase productivity over a very short period realising process transparency for all involved.

장점:

Understanding where our losses are with our manufacturing processes is what this software is designed for. The System is reliable and accurate with extensive a easy to understand and use functionality with a large selection of ready developed reports and templates. OEE Systems have worked with us to provide tools embedded in the software to provide the granularity of our process losses and highlight where these losses are live. The Team at OEE Systems are there with you to set up the systems and are always on hand to provide Systems and user Support.

단점:

If I'm being really critical the only thing for me is the display formatting but that's being really critical.

Using OEE to eliminate Non-Value-Adding activities.

주석: OEE is a very useful in managing downtime, machine (and operator) optimisation and identifying ways to add value throughout the value stream. It exposes the hidden costs within processes and procedures.

장점:

It did what it's supposed to do and more.

단점:

There is nothing at this stage that I can think of to identify a fault with the OEE software.

Excellent software for driving Continuous Improvement

주석: OEE Systems have provided a very high standard of customer service during the implementation of Perform OEE. The bespoke adaptations to the software have ensured the system works effectively within our production process and meets our needs for data reporting. The level of detail that is available at the click of a button has already proved to be invaluable by reducing the time spent recording and collating data. We look forward to making further tangible process improvements by actioning the data from Perform OEE over the coming weeks and months.

장점:

PerformOEE has become a vital tool for live monitoring of process performance and the identification of downtime root causes and improvement opportunities. The Reports Module makes it quick and easy to trend and analyse large amounts of data.

단점:

I am yet to find a feature of the software which I dislike.